What is a River Table and How is it Made?

Discover the fascinating world of river tables and learn how these stunning pieces of furniture are made. From the unique materials used to the intricate process of creating the flowing river effect, let’s explore what a river table is, how it’s crafted, and how it can serve as a statement in your home. Whether you’re a homeowner looking to elevate your space or an interior design enthusiast, this blog is for you.

What is a River Table?

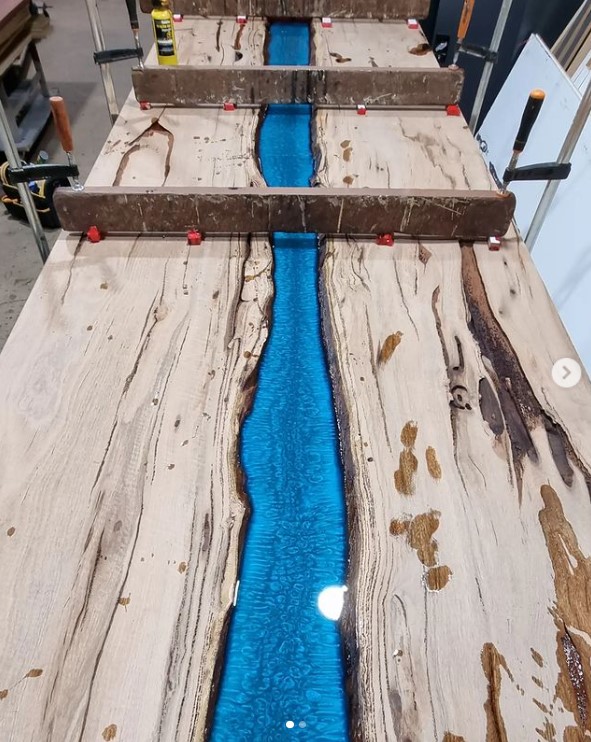

As the name suggests, a river table is a type of furniture that combines natural wood with epoxy resin to mimic the beautiful, flowing appearance of a river. This modern furniture piece has gained popularity for its striking appearance and the way it seamlessly combines natural elements with contemporary design.

The unique features and characteristics of a river table include its ability to showcase the natural beauty of wood while adding a touch of modern artistry to any room. The flowing resin creates a mesmerising visual effect, resembling a meandering river or a tranquil stream, making each piece one-of-a-kind.

Materials Used in River Table Making

There are a number of materials needed to make a river table, with each being customisable to achieve a unique piece of furniture. Let’s explore the key components to making a river table.

Epoxy Resin

Epoxy resin is a key component in creating the river effect for the table. It is a versatile and durable material that can be clear or tinted with various pigments and dyes to achieve your desired colour and transparency.

The resin is resistant to heat and moisture and cures to a glossy finish that can be polished for a high shine. Epoxy resin is also known for its ability to bond well with wood, creating a strong and long-lasting finish.

Wood Types

High-quality wood is essential for crafting a river table. Common wood types used for Australian-made pieces include Marri, Jarrah, and Oak, each with its own unique grain patterns and natural beauty. The choice of wood can greatly influence the overall appearance of the table, from the warmth of walnut to the elegance of maple.

Pigments and Dyes

Pigments and dyes are used to colour the epoxy resin, allowing for endless customization options. Whether it’s a deep blue to mimic the look of water or a vibrant red for a bold statement, the pigments and dyes add depth and character to the river table, enhancing its visual appeal.

Crafting a River Table

Crafting a river table is a meticulous process that blends the wood with the epoxy resin. Here are the steps to create these statement pieces of furniture.

Selecting and Preparing the Wood

The process begins with carefully selecting the right pieces of wood that will form the tabletop. The slabs are often chosen for their unique grain patterns and natural imperfections, adding to the organic feel of the final piece.

Once selected, the wood needs to be prepared which involves planing, sanding, and sometimes cutting the slabs to create a flat, smooth surface.

Designing the River

The wood slabs need to be positioned to define the river’s path and determine the width of the river. This step involves visualising the final product and adjusting the wood slabs to achieve your desired aesthetic.

Creating the Mould and Sealing the Wood

A mould is created to contain the epoxy resin as it cures. The mould is designed to follow the natural contours of the wood, ensuring that the resin flows in a way that complements the wood grain, creating the desired river-like effect.

A sealant will also need to be applied to the wood, especially around the edges that will contact the resin. This prevents the resin from seeping into the wood and causing bubbles or uneven curing.

Mixing and Pouring the Epoxy Resin

The epoxy resin is mixed with the chosen pigments or dyes until the desired colour is achieved. The resin is then carefully poured into the gap between the wood slabs, ensuring it fills the mould evenly. This step requires precision and expertise to achieve the perfect balance of transparency and colour, as well as to prevent air bubbles from forming.

Finishing and Polishing

After the resin has cured, the table is carefully sanded and polished to reveal the natural beauty of the wood and the mesmerising flow of the resin. This final step brings out the lustre of the materials and ensures a smooth, flawless surface.

Elevate your Space with Jarrimber

When you’re looking for a furniture piece that is sure to make a statement and spark conversation with visitors to your home, look no further than a Jarrimber river table. Our epoxy resin tables are made with the highest quality resin and make the perfect addition to any room in your home.

At Jarrimber, we specialise in making hand-crafted bespoke furniture, including resin river tables which are made with Australian and ethically-sourced materials.

We have custom design options, whether it be design or size, to suit your personal style and preferences. Whether you prefer a bold, colourful resin river table for your dining room, or a more subtle and natural look for your home office, our team can work with you to create a piece that reflects your aesthetic and complements your existing decor. If you’d like to discuss some ideas or just want to find out more about our products, get in touch with our friendly team and we’ll be happy to assist.

Share This